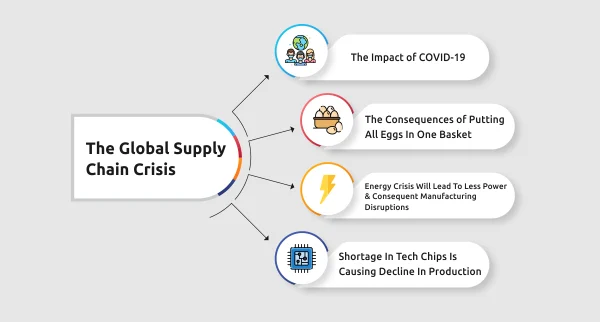

The Global Supply Chain Crisis has become a major concern in the business world. The COVID-19 pandemic, trade tensions, and natural disasters have all contributed to disruptions in the global supply chain, leading to shortages and delays. Companies are struggling to find solutions to this crisis, as it impacts their ability to meet customer demand and maintain efficient operations. Understanding the causes of this crisis and finding effective solutions is crucial for businesses to navigate through these challenging times.

The Global Supply Chain Crisis, also known as the Supply Chain Disruption, has brought attention to the vulnerabilities and interconnectedness of global supply chains. The shortage of raw materials, transportation bottlenecks, and labor constraints are all contributing factors to this crisis. As companies rely on just-in-time inventory and lean supply chains, any disruption can have a domino effect on the entire system. Finding alternative suppliers, improving inventory management, and investing in technology are some of the strategies that companies are exploring to address this crisis.

Global Supply Chain Crisis: Causes and Solutions

The global supply chain crisis has been a major concern for businesses and consumers around the world. The crisis has been caused by a combination of factors, including the COVID-19 pandemic, labor shortages, transportation challenges, and increased demand for goods. These factors have created a perfect storm that has disrupted the flow of goods and led to shortages of essential items. As a result, businesses have been struggling to meet customer demand, and consumers have been facing higher prices and longer wait times for products. Understanding the causes of the supply chain crisis is crucial in finding effective solutions to address the challenges it presents.

One of the main causes of the global supply chain crisis is the impact of the COVID-19 pandemic on global trade and logistics. The pandemic led to factory closures, labor shortages, and restrictions on international travel, which disrupted the production and transportation of goods. Additionally, the surge in demand for certain products, such as personal protective equipment and medical supplies, further strained the supply chain. These disruptions have highlighted the vulnerabilities of the global supply chain and the need for more resilient and flexible systems. Addressing these underlying issues is essential to building a more robust and adaptable supply chain for the future.

Impact of Labor Shortages on the Supply Chain

Labor shortages have had a significant impact on the global supply chain, contributing to delays and disruptions in the production and delivery of goods. The pandemic has led to workforce challenges, including illness-related absences, childcare responsibilities, and hesitancy to return to work in certain industries. These factors have affected various stages of the supply chain, from manufacturing and packaging to distribution and retail. As a result, businesses have struggled to maintain regular operations and meet consumer demand. Finding solutions to address labor shortages, such as implementing flexible work arrangements, offering incentives for workers, and investing in automation technologies, is crucial for mitigating the impact on the supply chain.

Furthermore, the global supply chain crisis has been exacerbated by transportation challenges, including port congestion, shipping delays, and a shortage of shipping containers. The imbalance of trade flows, limited capacity on container ships, and logistical bottlenecks have all contributed to the difficulties in moving goods across borders. These challenges have led to increased lead times, higher transportation costs, and a lack of available inventory. To alleviate these issues, stakeholders in the supply chain need to collaborate on developing more efficient and resilient transportation networks, optimizing routes, and investing in infrastructure to support smoother movement of goods.

Increased Demand and Inventory Management

The surge in consumer demand for goods, particularly in e-commerce, has put pressure on the global supply chain and strained inventory management systems. As more people turned to online shopping during the pandemic, businesses faced challenges in forecasting demand, managing stock levels, and fulfilling orders in a timely manner. The mismatch between supply and demand has led to stockouts, backorders, and longer delivery times, impacting customer satisfaction and loyalty. Implementing advanced forecasting and inventory management tools, diversifying sourcing strategies, and improving communication and collaboration with suppliers are essential for addressing the imbalances in demand and supply.

Moreover, geopolitical factors, trade policies, and tariff disputes have also contributed to the complexity of the global supply chain and influenced sourcing decisions and production locations. Uncertainties related to trade agreements, tariffs, and sanctions can disrupt supply chain operations and affect sourcing costs. Mitigating these geopolitical risks requires businesses to assess their supply chain vulnerabilities, diversify sourcing regions, and stay informed about international trade developments. Additionally, fostering transparency and ethical practices in sourcing and procurement can help build more resilient and sustainable supply chains.

| Causes | Solutions |

|---|---|

| 1. Disruptions due to COVID-19 | 1. Diversifying sourcing locations |

| 2. Increased consumer demand | 2. Improving inventory management |

| 3. Labor shortages | 3. Investing in technology for better visibility |

The global supply chain crisis has been caused by disruptions due to COVID-19, increased consumer demand, and labor shortages. To address these issues, companies are diversifying sourcing locations, improving inventory management, and investing in technology for better visibility.